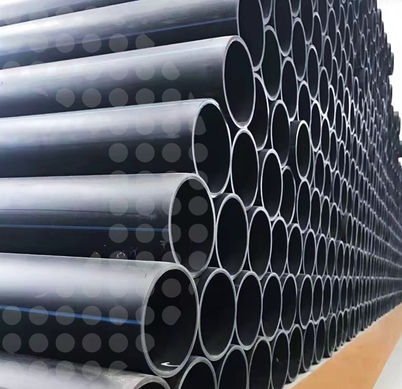

THERMOPLASTIC PIPING

SYSTEMS

-

Supply and Installation of Thermo Plastic Systems.

1

ADVANTAGES OF THERMOPLASTIC PIPING

-

Low Thermal Conduction

The transmission of heat is greatly reduced through plastics. -

Resistance Through Galvanic Corrosion

The electric conductivity of most plastics is very low, therefor they are not affected by galvanic or electrolytic corrosion induced by electrolytes such as acids, bases & salts. Thermoplastic piping are not vulnerable to biological attack. -

Chemical Resistance

The resistance to chemicals can be far more superior to metallic piping. There is a thermoplastic pipe that will handle about any acid, solvents, halogen, base or corrosive medium. -

Maintenance Free

Exterior corrosion is non-existent with Thermoplastic pipes. There is no rust, scale or pitted surface compared to metallic. -

Smooth Internal Surface

Plastic surface does not change over time and unlike metals, will maintain that same smooth finish long after installation. -

Low Installed Cost

Installation costs is lower because Thermoplastic piping is easier to handle. Less manpower is needed to carry, cut, prepare, thread, weld and hang plastic pipe compared to other materials. -

Flexibility

Unlike metals, plastic pipes are relatively flexible and can easily adapt to minor changes in direction resulting in savings during installations. -

Produced with Less Energy

Less than 50% of the energy is required to produce plastic fittings as for the same metal part. -

Less Weight

The lower weight in plastics results in smaller pipe racks, lower transportation costs, smaller supports and less manpower needed to install. -

Non Toxic

Plastics can transport almost any fluid safely without concern about contamination, from high purity water to the most sensitive media. -

Wide Temperature Range

Plastic piping can be specified to operate between -40 Degree C to 150 Degree C.

2

DISADVANTAGES OF THERMOPLASTIC SYSTEMS

Although Thermoplastics may be considered an ideal materials, it would only be fair to point out the disadvantages. Most of these disadvantages could however be negated in proper design and installation.

-

Rate of Thermal Expansion

Plastic pipes rate of linear thermal expansion is roughly 10 times more than metal pipes. This can cause dip, sag or "spaghetti" lines if system are not designed and installed correctly. -

Low Impact Strength

Compared to steel, plastics have a relatively low ability to withstand sharp impact. If a pipeline will see periodic foot traffic or possible contact with heavy equipment, adequate protection must be designed into the system. -

Flammability

Fire codes are quit specific as to when, where and how plastics can be installed safely in fire rated construction.

3

CAPABILITIES

We offer a wide selected range of connective systems and flow control suitable for the safe transport of water, chemicals, gasses and other media in a variety of applications:

Refrigeration:

-

ABS Range of Product

Chemical Processing

-

PVC - U Range of Products

-

PVC - C Range of Products

-

PE Range of Products

-

PVDF Range of Products

Our complete Range of products comprises of Piping, Fittings, Valves and Flow Control.

ABS, PE, PP, PVC-U, PVC-C & PVDF.

Valves

-

Diaphragm Valves

-

Ball Valves

-

3 Way Valves

-

Butterfly Valves

-

Pressure Reducing Valves

-

Non return valves in ball and wafer check style

Flow Control

-

Electric Actuation

-

Pneumatic Actuation

Instrumentation

-

Flow Measurement

-

PH

-

ORP

-

Conductivity

-

Resistivity

-

Pressure

-

Temperature

-

Level

-

Free Chlorine

-

Turbidity

-

Dissolved Oxygen

Having an installation team with certification we deliver high quality work ensuring safety.

Fabrication abilities of chemical acid baths, tanks and filters will make us your partner in material selection, designing, installing and maintaining your system.